Heavy-duty connectors are specifically designed to withstand harsh environments and are widely used in applications requiring electrical and signal connections, such as wind energy, robotics, construction machinery, textile machinery, packaging and printing machinery, tobacco machinery, electric locomotives, and petrochemical power. These settings often present challenges from temperature and humidity fluctuations as well as sustained vibrations, yet heavy-duty connectors ensure secure connections under complex conditions, enabling stable system operation.

Heavy-duty connectors offer durability, stability, and flexibility, excelling in harsh environments to provide data, signal, or electrical connections between various devices or functional units. They significantly enhance the installation and maintenance efficiency of complex control equipment. Their modular design and standardized interfaces maximize application efficiency. With the advancement of Industry 4.0, the demand for customization, stability, and integration in industrial equipment has increased. Continuous optimization of heavy-duty connectors now provides better options in terms of service, customization, and quality.

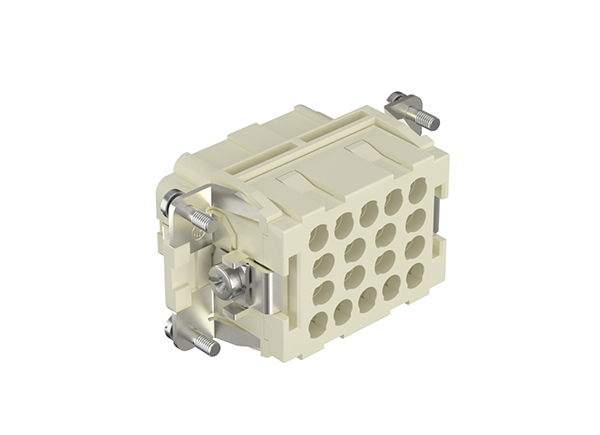

These connectors consist of three key components: inserts, contacts, and housings. The inserts and contacts form the electrical module, ensuring reliable electrical connections, while housings made of metal or thermoplastic materials provide mechanical and environmental protection. The metal housings are water-resistant and corrosion-resistant, enabling heavy-duty connectors to function in demanding environments and meet outdoor connectivity requirements. The comprehensive product range accommodates current ratings from 5A to 350A, and the modular design allows customers to define connection interfaces based on specific needs, easily achieving customized connections.

Moreover, customer service has seen significant improvements. A professional engineering team provides full support, combining project management with cable assembly integration services to significantly enhance the quality and efficiency of client projects. The standard delivery time for heavy-duty connectors is approximately one week, meeting clients’ time-sensitive demands.

The Greater the Challenge, the Greater the Connector's Responsibility

Harsh environments, such as remote mountainous areas or deserts, impose extreme natural conditions on electronic systems and infrastructure, including temperature and humidity variations, wind and sand, rainstorms, and ice and snow, which can easily lead to equipment failures. High-quality heavy-duty connectors can reduce system failure rates, providing robust support for equipment in remote locations and ensuring more stable system operation.

Leave a comment